I heard a very interesting thing when I went on a factory tour at MKS.

This is the pedal axle of MKS pedals. The center of the pedals. It’s like spines for humans.

These axles are actually made by forging, not cut processing.

They evolve into the final product step by step, goes through four different machines.

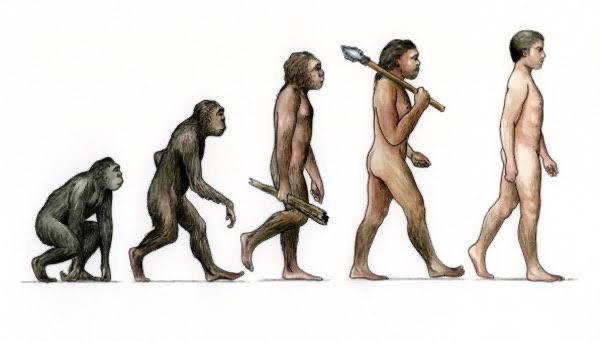

This process makes the axles to be stiffer than the others in the market since it’s one thick piece of metal being smashed into the final shape instead of cutting the piece of metal. It’s like a gorilla turning into a human with its original weight.

Another secret is in the metal material they use. MKS uses an incomparably sticky metal than the other pedal companies, this adds even more durability to the axles which makes it possible to have the unbreakable quality.

Due to the sticky metal material they use, there are no other choices to forge them instead of cutting them. Ain’t that amazing?

This is the actual picture of the machine to produce the axles.

Forging is one of the oldest way of processing metal. People used to make katanas and armors with forging in the old days. We’ve seen it in movies and animes right? That is what forging is.

Is forging an old tradition that we rarely see? Not exactly, kitchen knives are still made with forging.

This processing method is still quite common it seems.

If you look at a bigger picture, crank shafts for automobiles and jet engines for airplanes are also made with forging.

Forging enables to produce stiff and tough metal components that is hard to deteriorate.

Isn’t it awesome that a small piece of metal in a bicycle pedal is processed with the same way of processing a huge metal component that’s used in a plane that is never supposed to break?

That is how MKS is determined to be the world’s best bicycle pedal manufacturer.